The speed governor is the silent guardian of every elevator ride. This essential safety device continuously monitors the elevator car’s speed and instantly triggers emergency stopping mechanisms if the car exceeds safe limits—whether plunging downward in a free-fall or surging upward out of control. Without a properly functioning speed governor, an elevator lacks one of its most critical layers of protection against catastrophic failure.

At Panda Elevator, we integrate only the highest-quality speed governors into every system we design, install, and maintain. These components work seamlessly with safety gears, rope brakes, and upward protection devices to ensure passenger safety under all operating conditions. This comprehensive guide explains how speed governors work, the key differences between unidirectional and bidirectional types, and how Panda Elevator selects and services these vital components to deliver unmatched reliability.

A speed governor operates through a precise mechanical and electrical system. A governor rope connects to the elevator car and loops around a rotating sheave (rope wheel). As the car moves, the sheave spins at a speed proportional to the car’s velocity. Inside the governor, centrifugal flyweights or spring-loaded mechanisms respond to this rotation.

When the car exceeds the rated speed—typically by 15% or more—the flyweights extend due to centrifugal force, tripping a mechanical latch. This action simultaneously:

The result? The elevator car stops smoothly and safely within a regulated distance, regardless of load or direction of travel. Modern Panda Elevator systems incorporate governors with remote testing capabilities, allowing technicians to verify functionality electronically without entering the hoistway—reducing downtime and enhancing safety compliance.

Speed governors fall into two primary categories based on the direction of overspeed they protect against. Panda Elevator carefully selects the appropriate type for each installation to match the elevator’s speed, layout, and safety requirements.

Unidirectional governors protect against overspeed in a single direction—almost always downward. They are the standard choice for most passenger and freight elevators where the primary risk is car free-fall due to traction loss, brake failure, or counterweight issues.

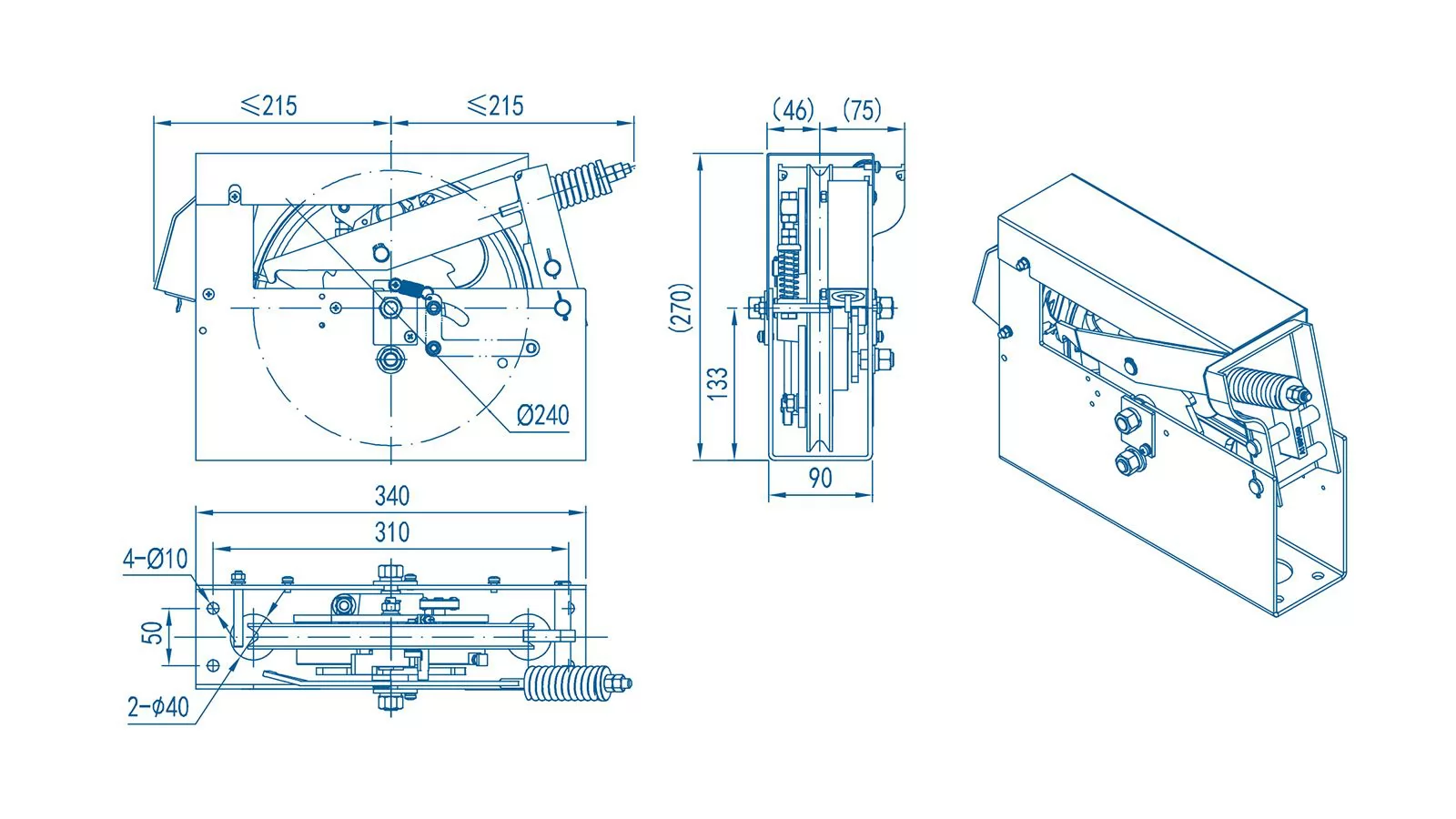

Panda Elevator uses unidirectional governors in machine-room and many machine-roomless (MRL) applications up to 2.5 m/s. These units feature robust 200–240 mm diameter rope wheels, compatibility with 6–8 mm governor ropes, and a minimum pulling force of 500 N to ensure reliable safety gear activation. Remote electrical testing and automatic switch reset are standard in our premium installations, enabling fast, safe maintenance.

Bidirectional governors provide dual-direction protection—stopping the car during both excessive downward speed and uncontrolled upward movement. This is critical in high-speed elevators, MRL systems, and any application requiring Unintended Car Movement Protection (UCMP).

Panda Elevator specifies bidirectional governors for:

Our bidirectional models support rope diameters from 6 to 8 mm, pulling forces ≥500 N, and include advanced UCMP detection logic. Remote testing, dual-action safety gear control, and auto-reset functionality ensure compliance with the latest EN 81-20/50 and ASME A17.1 standards.

| Panda Model Series | Rated Speed (m/s) | Rope Wheel Ø (mm) | Rope Ø (mm) | Pulling Force | Direction | Control Options |

|---|---|---|---|---|---|---|

| Panda OX-240 | ≤2.5 | 240 | 6 / 8 | ≥500 N | Unidirectional | Safety Gear |

| Panda OX-240B | ≤2.5 | 240 | 8 | ≥500 N | Bidirectional | Safety Gear + Rope Brake |

| Panda OX-208 | ≤1.75 | 200 | 6 | ≥500 N | Unidirectional | Safety Gear + Remote Test |

| Panda OX-186 | ≤0.63 | 200 | 6 | ≥500 N | Bidirectional | Dual Safety Gear |

| Panda OX-186A | ≤0.4 | 150 | 6 | ≥500 N | Bidirectional | Dual Safety Gear + Remote |

Proper installation is the foundation of speed governor reliability. Panda Elevator follows strict protocols for every project:

All Panda Elevator installations include:

Our engineering team evaluates every project using a structured selection process:

For a 1.75 m/s passenger elevator in a 15-story building, Panda Elevator might specify the Panda OX-240B bidirectional governor with remote testing and UCMP—ensuring full protection and future-proof compliance.

We treat speed governor maintenance with the same rigor as emergency response planning. Our certified technicians perform:

All test data is logged digitally and accessible via Panda Elevator’s client portal. Predictive maintenance alerts notify building managers before issues escalate.

Every speed governor in a Panda Elevator system carries:

We assist building owners with inspection preparation, providing all required certificates and test logs to streamline regulatory approvals.

| Symptom | Likely Cause | Panda Fix |

|---|---|---|

| False tripping | Rope slip or vibration | Realign sheave, adjust tension |

| No reset after test | Switch fault | Replace microswitch module |

| UCMP error code | Sensor drift | Recalibrate or replace sensor |

| Slow engagement | Worn linkage | Inspect and lubricate pivots |

Our 24/7 emergency response team resolves 95% of governor issues within 4 hours of dispatch.

Panda Elevator doesn’t just install components—we engineer safety ecosystems. Our speed governors feature:

From compact home lifts to 6 m/s skyscraper express elevators, Panda Elevator delivers speed governors that protect lives, reduce liability, and minimize downtime.

The speed governor is not just another component—it’s the last line of defense between normal operation and disaster. Panda Elevator has made it our mission to ensure every elevator we touch is equipped with governors that exceed industry standards for performance, reliability, and ease of maintenance.

Whether you’re upgrading an existing building, constructing a new high-rise, or retrofitting for UCMP compliance, Panda Elevator has the expertise and product range to keep your passengers safe. Contact our engineering team today for a free safety assessment and discover why leading property managers trust Panda Elevator for life-critical systems.