Every day, millions step into elevators, trusting these machines to ferry them safely between floors. But what happens when an elevator malfunctions, hurtling toward the bottom of the shaft? Enter the elevator buffer—a silent, unassuming device that stands as the last line of defense against catastrophe. Often overlooked, elevator buffers are the unsung heroes of vertical transportation, absorbing kinetic energy to prevent disastrous impacts. In this comprehensive guide, we’ll unravel the mystery of elevator buffers, exploring their types, mechanics, maintenance needs, and their evolving role in a world of smart buildings. With insights from Panda Elevator, a leader in innovative elevator solutions, this article will not only inform but also inspire confidence in the safety systems that keep us moving.

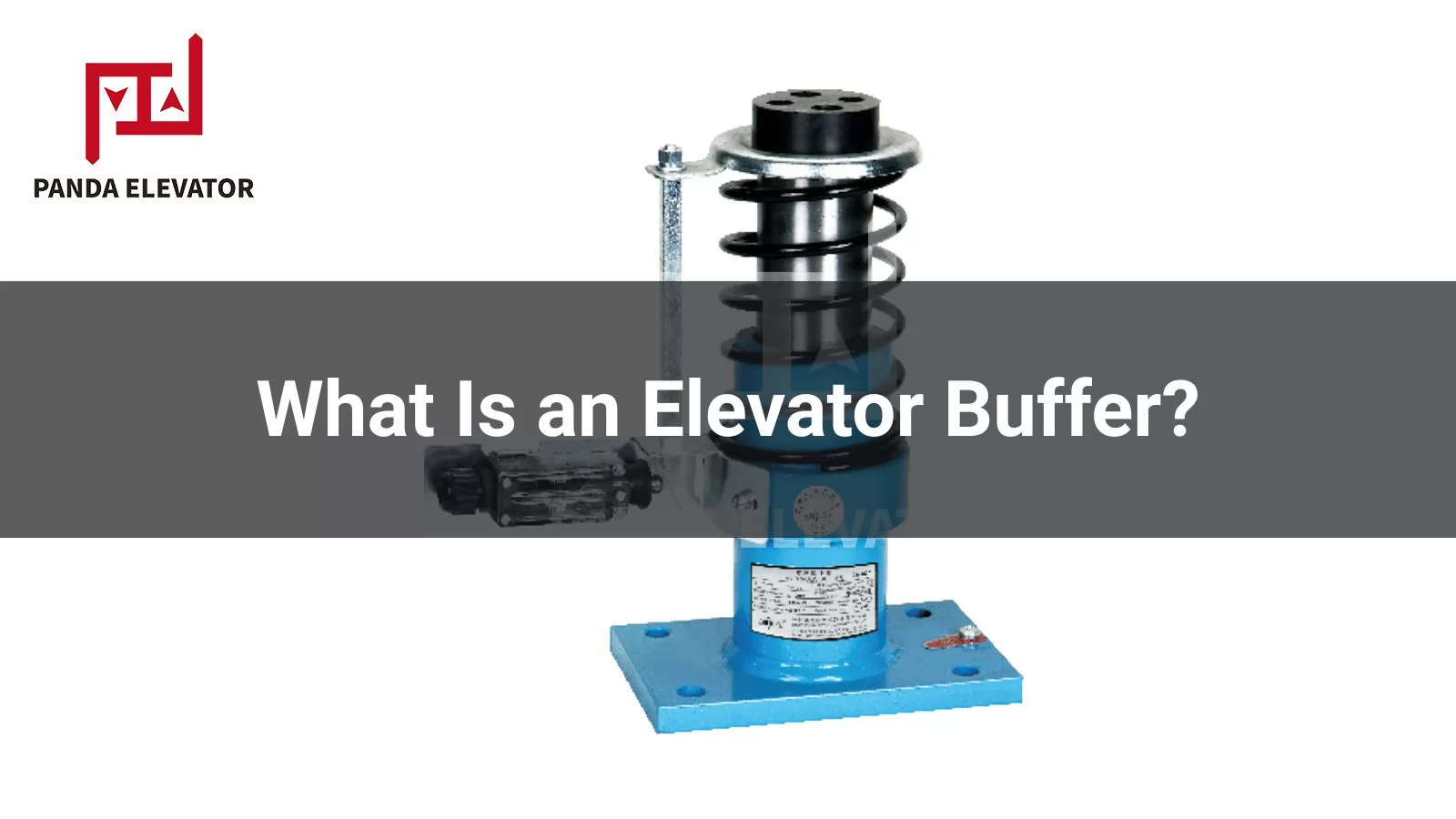

An elevator buffer is a safety device installed at the bottom of an elevator shaft, designed to absorb and dissipate the kinetic energy of a falling elevator car or counterweight. Think of it as a shock absorber that cushions the impact, preventing damage to the elevator and injury to passengers. When an elevator overshoots its lowest floor due to mechanical failure, rope breakage, or control system errors, the buffer steps in to ensure a controlled stop. According to international standards like ASME A17.1 and EN 81, buffers must limit the average deceleration to 1g (gravitational acceleration) and peak deceleration to 2.5g for no more than 40 milliseconds, ensuring passenger safety even in worst-case scenarios.But buffers are more than just mechanical components—they embody the principle of redundancy in engineering. They work in tandem with other safety systems, like overspeed governors and safety brakes, forming a multi-layered shield. For Panda Elevator, buffers are a testament to their commitment to blending precision engineering with human-centric design, ensuring every ride is as safe as it is smooth.

Not all elevators are created equal, and neither are their buffers. Depending on the elevator’s speed, load, and application, different buffer types are employed. Let’s dive into the three primary categories, each tailored to specific needs.

1. Polyurethane Buffer: A polyurethane buffer is a critical safety component widely used in modern elevator systems, typically installed in the pit as an alternative to traditional hydraulic buffers. Made from high-performance cellular polyurethane elastomer, it excels in impact resistance, oil resistance, aging resistance, and weather durability. In the event of an overspeed or emergency descent, the buffer absorbs and dissipates massive kinetic energy through controlled compression of its honeycomb-like microcellular structure, significantly reducing impact acceleration and protecting passengers and equipment. Compared with oil buffers, polyurethane buffers offer zero risk of oil leakage, require no maintenance, are easy to install, and are suitable for elevators with rated speeds up to 2.0 m/s, making them the preferred choice for mid- and low-speed passenger and freight elevators today.

2. Hydraulic Buffers: Precision for High StakesFor mid-to-high-speed elevators (>1 m/s or 200 ft/min), hydraulic buffers take center stage. These devices use a piston and hydraulic fluid to control deceleration, pumping oil through orifices to dissipate energy smoothly. Found in high-rise office towers and heavy-duty freight elevators, hydraulic buffers excel at preventing rebound and ensuring a gradual stop. Their downside? They require regular maintenance to check fluid levels and prevent leaks, especially in flood-prone environments.Panda Elevator’s hydraulic buffers are engineered to meet stringent ASME A17.1 and GB 7588 standards, undergoing rigorous testing to handle 115% of rated speed in free-fall scenarios, ensuring safety in demanding applications.

Understanding the mechanics of elevator buffers reveals their engineering brilliance. When an elevator car or counterweight exceeds its normal travel limits, safety systems like the overspeed governor or safety clamps activate first. If these fail, the buffer takes over. Upon impact, the buffer compresses, converting the kinetic energy of the falling mass into potential energy (in springs or polyurethane) or heat (in hydraulic systems). This process ensures the elevator decelerates gradually, keeping forces within safe limits for human passengers.For example, in a hydraulic buffer, the piston forces oil through small orifices, creating resistance that slows the elevator. The design ensures the average deceleration remains below 1g, preventing passengers from experiencing excessive jolts. Panda Elevator’s buffers are precision-tuned to match specific elevator parameters, such as load and speed, ensuring optimal performance in every installation.

Elevator buffers are more than a regulatory checkbox—they’re a lifeline. In a world where high-rise buildings dominate urban skylines, the stakes of elevator safety are higher than ever. A single buffer failure could lead to catastrophic damage or injury, especially in high-speed elevators traveling at 10 m/s or more. Data from global safety reports indicate that while buffer-related accidents are rare, their consequences are severe, underscoring the need for robust design and maintenance.Beyond protecting passengers, buffers safeguard the elevator itself, reducing repair costs and downtime. For building managers, this translates to lower operational expenses and enhanced tenant satisfaction. Panda Elevator’s commitment to quality buffers ensures that their systems not only meet but exceed safety standards, fostering trust in their brand.

Like any critical component, elevator buffers require regular attention to perform reliably. Here’s a breakdown of maintenance essentials:

Flood-prone elevator pits pose a unique challenge, as water can damage buffers, particularly hydraulic ones. Panda Elevator recommends waterproof seals and regular pit inspections to mitigate risks. Their maintenance packages include comprehensive buffer checks, ensuring compliance with standards like GB 7588 and ISO certifications.

At Panda Elevator, safety isn’t just a standard—it’s a promise. Their range of elevator buffers, from robust hydraulic models to eco-friendly polyurethane designs, reflects a commitment to quality and innovation. Each buffer is tailored to the specific needs of the project, whether it’s a towering skyscraper or a cozy residential building. With rigorous testing and adherence to global standards, Panda Elevator ensures that their buffers deliver peace of mind with every ride.Ready to elevate your building’s safety? Contact Panda Elevator to explore their cutting-edge buffer solutions and comprehensive maintenance services. Visit their website for more details on how they’re shaping the future of vertical transportation.

Elevator buffers may be out of sight, but their impact is undeniable. From spring buffers in quaint low-rises to smart polyurethane systems in futuristic skyscrapers, these devices are the backbone of elevator safety. By understanding their types, mechanics, and maintenance needs, building owners and passengers alike can appreciate the engineering that keeps us moving safely. With Panda Elevator leading the charge, the future of elevator buffers is not just about preventing accidents—it’s about building trust, sustainability, and innovation into every ride.

Answer: Regular maintenance is critical to ensure your elevator buffer performs in an emergency. Signs that maintenance is needed include visible corrosion on spring buffers, oil leaks or low fluid levels in hydraulic buffers, or reduced elasticity in polyurethane buffers. Experts recommend annual inspections, checking for alignment, fluid contamination, and structural integrity. For hydraulic buffers, monitor oil levels monthly, as low fluid can reduce effectiveness by up to 50%. Panda Elevator offers maintenance plans that include buffer health checks, ensuring compliance with standards like GB 7588 and ASME A17.1. Schedule a professional inspection if your elevator is in a high-traffic building or flood-prone area to prevent costly failures.

Answer: A failing elevator buffer can lead to severe consequences, including elevator damage, passenger injuries, or even fatalities in extreme cases. If a buffer doesn’t absorb the kinetic energy of a falling elevator car, the impact could exceed safe deceleration limits (1g average, 2.5g peak), causing structural damage or harm to occupants. For example, a 2020 study found that buffer-related failures, though rare (less than 2% of elevator incidents), accounted for significant repair costs. Regular testing and maintenance, as emphasized by Panda Elevator, can prevent such risks, ensuring buffers perform reliably during free-fall scenarios.

Answer: Polyurethane buffers often have a higher upfront cost than spring or hydraulic buffers, but their benefits can outweigh the expense. They require minimal maintenance, are resistant to oil leaks, and offer superior durability, lasting up to 20 years in optimal conditions. Their eco-friendly design also aligns with green building standards, making them ideal for sustainable projects. For mid-speed elevators in commercial or residential settings, polyurethane buffers can reduce long-term costs by up to 30% compared to hydraulic systems due to lower maintenance needs. Panda Elevator’s polyurethane buffers are a smart choice for building owners prioritizing sustainability and reliability.

Answer: While elevator buffers are critical safety components, they are not a cure-all. Buffers are designed to handle specific scenarios, like overspeed or free-fall incidents, but they work as part of a broader safety system, including overspeed governors and safety clamps. If other systems fail or maintenance is neglected, buffers alone may not prevent accidents. For instance, improper installation can reduce buffer effectiveness by 40%. Panda Elevator ensures their buffers are rigorously tested to meet global standards, but they stress the importance of holistic maintenance to maximize safety. Regular inspections and compliance with standards like EN 81 are key to minimizing risks.

Answer: The future of elevator buffers is leaning toward smart, sustainable solutions. Innovations like AI-integrated buffers with sensors to monitor wear and predict maintenance needs are on the horizon. These systems could reduce elevator downtime by up to 50% by alerting technicians to issues before they escalate. Additionally, eco-friendly materials like advanced polymers are gaining traction, aligning with green building trends. Panda Elevator is at the forefront, exploring smart buffer technologies to enhance safety and efficiency in high-rise environments, ensuring elevators keep pace with smart city demands.