_1770604422_WNo_1600d900.webp)

An elevator that stops even slightly above or below the floor can create safety risks. This is why elevator leveling sensors are essential in modern elevator systems.

These sensors ensure the elevator car stops at the exact floor height before the doors open. The result is safer passenger movement, smoother entry and exit, and improved ride comfort.

In commercial buildings, hospitals, factories, and residential towers, accurate elevator leveling is not optional—it is a core safety requirement.

By providing real-time position feedback to the elevator control system, leveling sensors help:

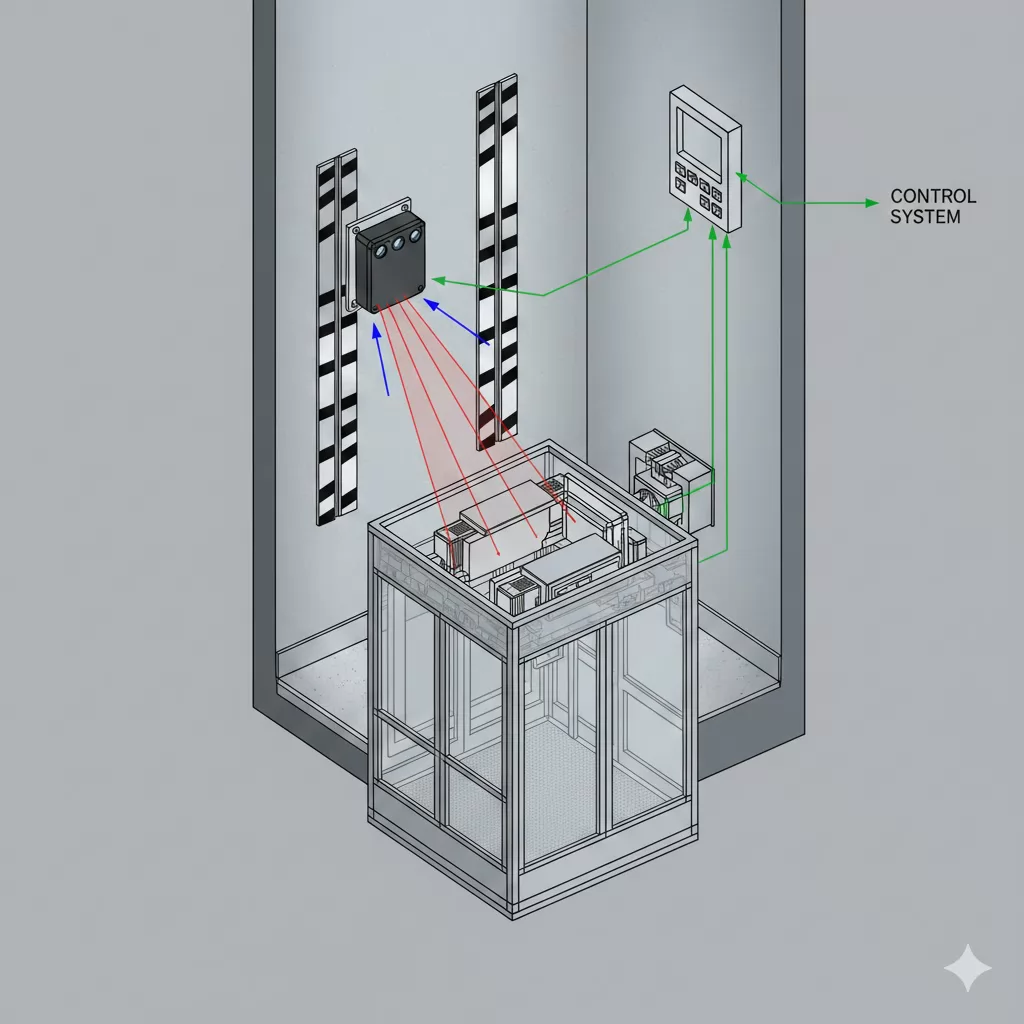

An elevator leveling sensor is a precision position-sensing device that detects when an elevator car reaches the correct floor level. It works together with the elevator control system to achieve accurate and stable stopping.

The sensor identifies reference points installed inside the elevator shaft, such as:

When the elevator approaches a floor, the leveling sensor detects these reference points and sends a signal to the controller. This signal activates the leveling (creeping) phase, during which the elevator slows down and performs fine positional adjustments.

Only after the elevator car floor is precisely aligned with the building’s floor sill will the doors be allowed to open. This process ensures consistent leveling accuracy, even when load conditions or mechanical factors change.

Because of this continuous feedback and correction capability, elevator leveling sensors are a critical part of any modern elevator leveling system, supporting safety, reliability, and long-term performance.

An elevator leveling sensor works by continuously monitoring the vertical position of the elevator car as it moves inside the shaft. Its goal is simple but critical: ensure the car stops at the exact floor level.

The leveling process can be divided into several precise steps.

As the elevator travels, the leveling sensor scans for predefined reference points installed along the elevator shaft. These reference points indicate the exact stopping position for each floor.

Depending on the sensor type, these reference points may include:

When the elevator car approaches a floor, the sensor detects the corresponding reference point and determines the car’s relative position in real time.

Once the correct reference point is detected, the leveling sensor immediately sends an electrical signal to the elevator control system. This signal confirms that the car is entering the leveling zone.

The controller uses this information to calculate precise stopping commands, taking into account speed, load, and travel direction.

After receiving the signal, the controller activates the leveling or creeping phase. During this stage, the elevator slows down significantly.

Small, controlled movements are then applied to fine-tune the car’s position. This allows the system to correct minor deviations caused by load changes or mechanical tolerances.

The elevator continues adjusting until the car floor is perfectly aligned with the building’s floor sill. Only when this alignment falls within the allowed safety tolerance will the system permit door opening.

This final verification step prevents uneven stops, premature door operation, and long-term wear on elevator components.

Through this step-by-step process, elevator leveling sensors ensure safe stopping, smooth passenger flow, and reliable long-term operation in modern elevator systems.

Elevator leveling sensors use different sensing technologies depending on elevator design, operating environment, and accuracy requirements. Each type has its own strengths and typical applications.

Magnetic leveling sensors are among the most commonly used solutions in modern elevator systems. They detect magnetic fields generated by magnetic strips or targets installed in the elevator shaft.

These sensors typically operate using Hall-effect or reed switch technology. When the elevator car passes a magnetic reference point, the sensor detects the magnetic field change and sends a position signal to the controller.

Key advantages of magnetic leveling sensors include:

They are widely used in passenger elevators, freight elevators, and modernization projects.

Photoelectric leveling sensors use light beams—such as infrared or laser—to detect floor-level reference points. They measure position based on light reflection or interruption.

These sensors offer fast response times and high positioning accuracy, making them suitable for elevators that require precise stopping performance.

Typical advantages include:

Photoelectric sensors are commonly used in high-speed and high-traffic elevator systems.

Inductive proximity sensors are non-contact devices designed to detect metal objects. In elevator applications, they sense metal vanes or plates installed at specific floor positions.

When a metal target enters the sensor’s electromagnetic field, the sensor generates a signal indicating proximity. This signal is then used for leveling control.

Main benefits include:

They are often used in elevator door systems and short-range leveling detection.

Ultrasonic leveling sensors measure distance by emitting sound waves and analyzing the reflected echo. This allows the sensor to calculate the car’s position relative to the floor.

Because ultrasonic sensors are less affected by dust, moisture, or lighting conditions, they perform well in challenging environments.

Their key advantages include:

Ultrasonic sensors are typically used in industrial elevators and specialized applications.

Accurate elevator leveling is not just a technical detail. It directly affects passenger safety, accessibility, and system reliability.

When an elevator does not stop level with the floor, even small height differences can create serious hazards. This is especially critical in high-traffic public buildings.

Proper leveling helps prevent:

Modern buildings are required to meet strict accessibility standards. Accurate elevator leveling ensures smooth, step-free access for all users.

Consistent leveling also improves ride comfort by eliminating sudden stops, uneven landings, and repeated re-leveling movements.

Poor leveling forces elevator components to compensate for misalignment. Over time, this increases stress on doors, guide rails, brakes, and drive systems.

By maintaining precise stopping accuracy, elevator leveling sensors help:

Elevator systems must comply with international safety regulations and building codes. Accurate leveling is a mandatory requirement in many standards.

Reliable leveling sensors support compliance with widely recognized standards such as:

For building owners and maintenance providers, accurate elevator leveling is essential for passing inspections and ensuring long-term operational safety.

Elevator leveling sensors are used across a wide range of elevator systems. Different applications place different demands on accuracy, durability, and response speed.

In residential and commercial buildings, passenger elevators require smooth and precise stopping at every floor. Accurate leveling is essential for daily, high-frequency use.

Leveling sensors in passenger elevators help ensure:

Freight elevators often carry heavy or uneven loads. This makes precise leveling more challenging and more critical.

In industrial environments, leveling sensors must withstand:

Robust leveling sensors help maintain stability and safety during loading and unloading.

Hospitals rely on elevator systems for patient transport, medical equipment, and emergency operations. Even minor leveling errors can cause disruptions.

Accurate elevator leveling ensures:

Many older elevators were not designed to meet today’s leveling accuracy standards. Modernization projects often include upgrading or replacing leveling sensors.

New leveling sensors can significantly improve:

This makes elevator leveling sensors a key component in modernization and retrofit solutions.

Selecting the right elevator leveling sensor is essential for ensuring long-term safety, accuracy, and system compatibility. The choice should be based on both technical requirements and operating conditions.

Different elevator systems place different demands on leveling performance. Passenger elevators, freight elevators, and medical elevators all require different levels of precision and durability.

When choosing a leveling sensor, consider:

The environment inside the elevator shaft can significantly affect sensor performance. Dust, moisture, vibration, and temperature variations must be taken into account.

For challenging environments, it is important to select sensors that offer:

The leveling sensor must be fully compatible with the existing elevator control system. Signal type, voltage requirements, and response time all need to match system specifications.

Using compatible sensors helps avoid:

Reliable leveling sensors reduce maintenance workload and downtime. Choosing durable, well-tested components can significantly lower long-term operating costs.

Key factors to evaluate include:

By carefully considering these factors, elevator operators and maintenance providers can select leveling sensors that deliver consistent performance and long-term reliability.

At Panda Elevator Parts, we offer high-quality elevator leveling sensors designed for modern elevator systems. Our sensors are engineered with precision, durability, and real-world performance in mind.

One featured model is the SGD31-GG-TZ2B2P elevator leveling sensor, optimized for continuous position feedback and precise floor alignment.

These sensors are suitable for passenger elevators, freight elevators, and modernization projects where accurate leveling and reliable operation are required.

Panda Elevator Parts is a one-stop supplier of elevator components with a wide product range covering safety parts, control systems, traction systems and more. Our products are backed by quality assurance and export experience to global markets.

For detailed specifications, installation guides, and pricing, you can view the full product page or contact our sales team for personalized support.

Elevator leveling sensors play a critical role in ensuring safe, accurate, and reliable elevator operation. By providing precise position feedback, they allow elevator systems to stop smoothly and align perfectly with each floor.

From understanding how elevator leveling sensors work to comparing different sensor technologies and applications, it is clear that accurate leveling is essential for passenger safety, accessibility, and long-term equipment performance. Choosing the right sensor helps reduce maintenance issues, extend service life, and meet international safety standards.

Whether used in new installations or modernization projects, high-quality elevator leveling sensors are a key component of modern elevator systems. By selecting reliable, well-matched sensors, building owners and maintenance providers can ensure consistent performance and confidence in everyday operation.